Configure Now

Items in Your Cart0

0Items in Your Cart

Start building your packageShop Now

GVIs are conducted from a moderate distance and provide a general overview of the hull status. Typically completed at approximately an arm’s length away from the component, operators are searching broadly for any defects or issues. While a mirror may be required to enhance visual access to exposed areas, a GVI is conducted under normally available lighting conditions. Daylight, flashlight or ROV lights are usually the only light used for GVI and sometimes nearby structures or objects may have to be moved out of the way to gain access.

A GVI looks to detect a number of things including:

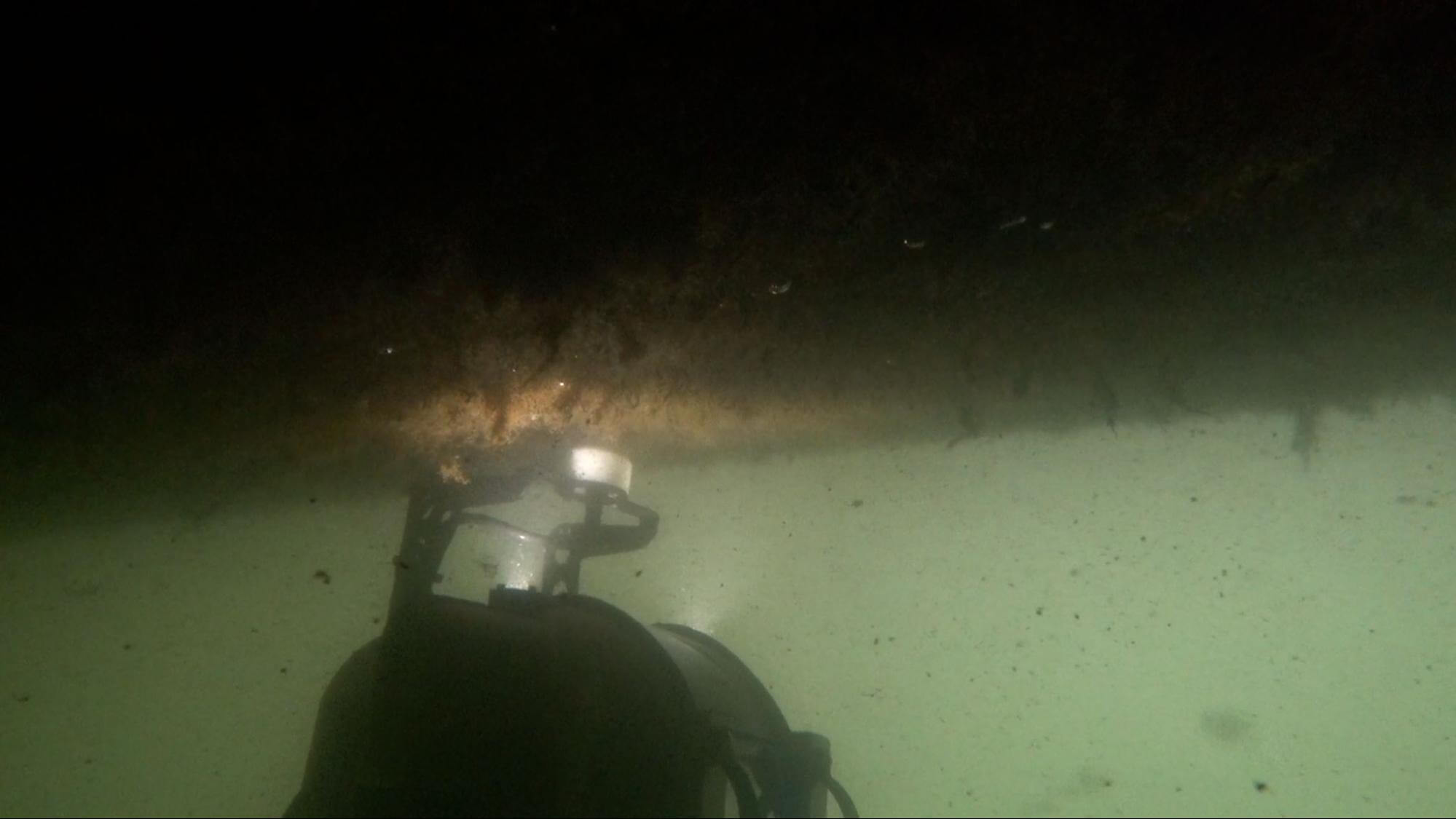

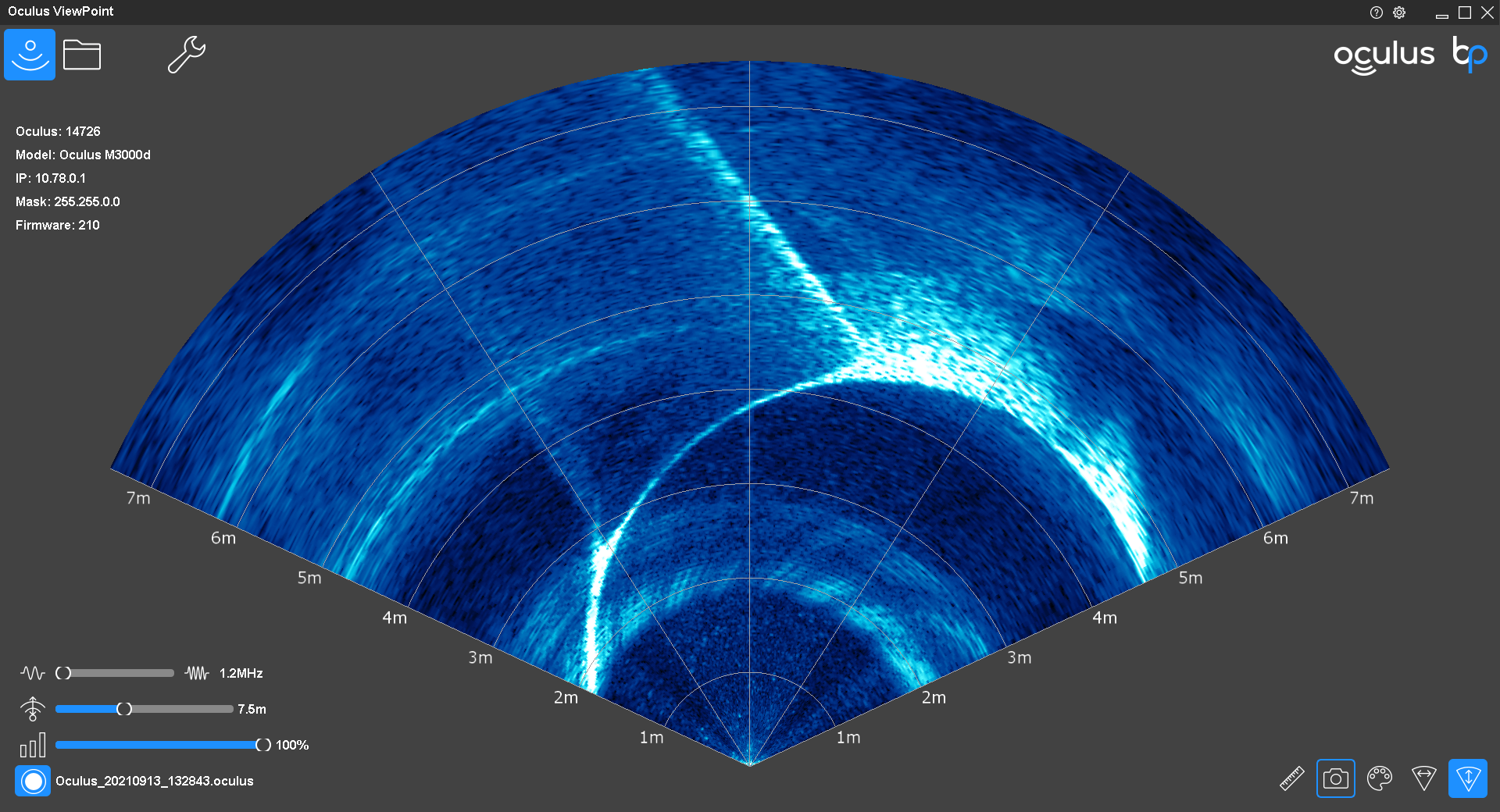

CVIs typically make use of additional equipment to enhance the quality of the inspection. Normally natural lighting is supplemented with a direct source of targeted light such as auxiliary lights or flashlight. In particularly murky or turbid waters, imaging sonar tools can also be utilized.

Furthermore, CVI often entails surface cleaning to gain clear access to all components of the area being inspected. Specific tools such as probes, gauges and measuring tools are also often used to acquire further insight into the hull or structure. Finally, more extreme access procedures may be required to ensure close inspection to all aspects of the component being inspected.

The qualifications applicable to CVI can be both PCN or CSWIP. A CVI is suitable for a number of structures and components including:

Read more about the difference between GVIs and CVIs here.

To dry-dock a vessel, the entire ship must be removed from the water and placed onto blocks. For large ships, this can be a complex and dangerous procedure, requiring a crew, heavy equipment, and a qualified dockmaster. In the event of a failing dry-dock block, the entire ship can capsize, resulting in catastrophic damage and danger to the crew. Due to the high cost, time usage, and potential complications, many are now opting for Underwater Inspections in lieu of Dry Docking.

To conduct a UWILD, the owner of the vessel must first ensure that they qualify. If there are outstanding recommendations for repairs to propellers, rudders, stern frames, sea valves or other underwater structures, dry-docking may be the only suitable option (ABS 2015). Once qualified, UWILDs have been performed by ABS certified divers traditionally. The divers will navigate under the hull of a ship to conduct visual inspections as needed. To further elevate the efficiency of UWILDs over dry-dockings, new equipment such as ROVs are rapidly becoming more popular to eliminate the need for dive teams.

To learn more about UWILD best practices, check out our full article here.

Knowing the complete list of components to inspect on each vessel is integral for a thorough inspection. Ships can have a great variety of different designs, so pre-identifying the number and location of each key component can help reduce the time needed for inspections. The main vessel components to inspect are:

The respective inspector will then assign whether the ship is in need of repair, requires further monitoring, or in good condition. For Coast Guard inspections, security inspections for contraband may also be conducted. This extra step monitors for potentially dangerous items, illegal goods, or unregistered crew members.

Deploy a ROV to perform quick, safe and affordable hull inspections

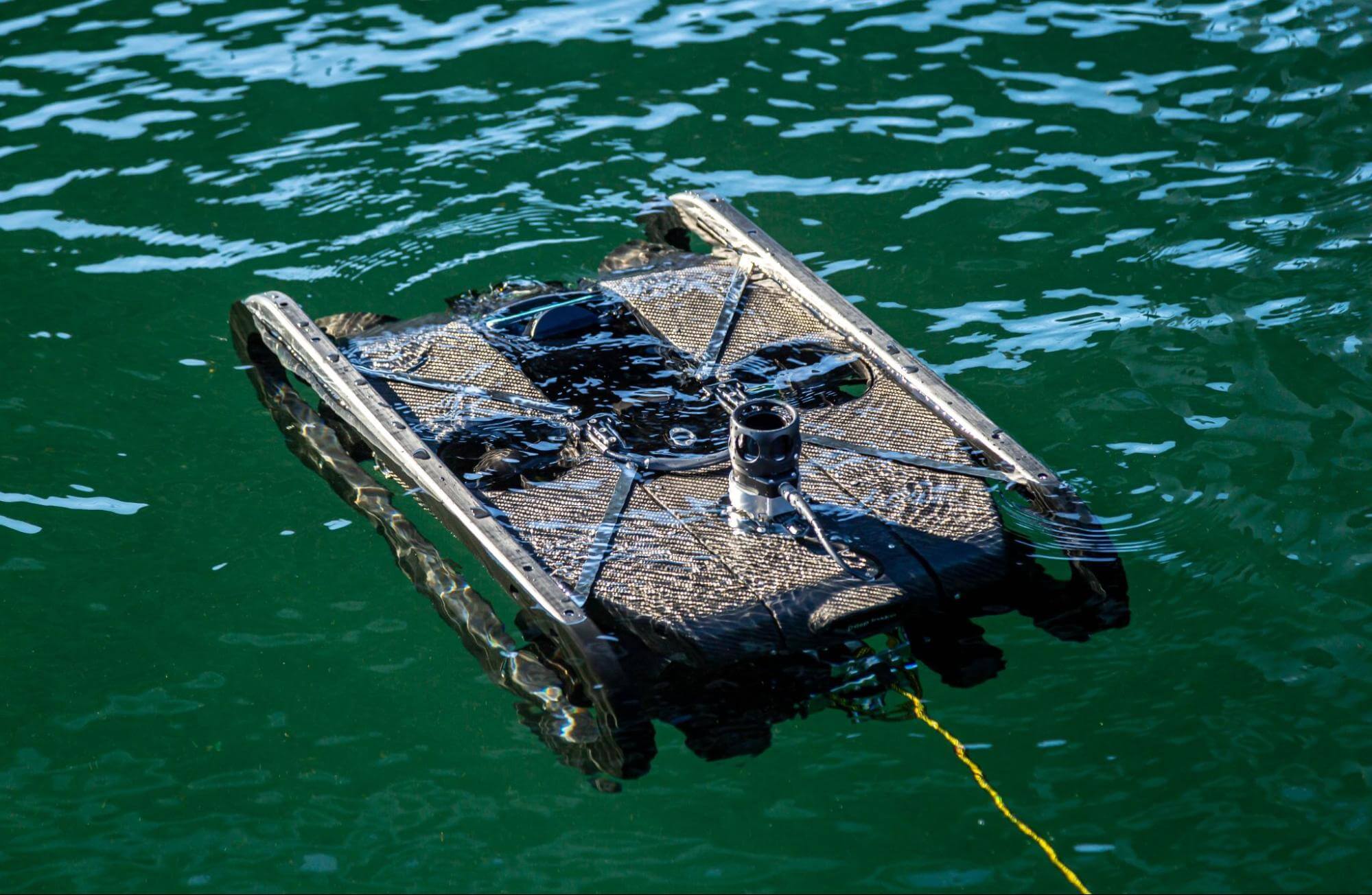

With the introduction of ROVs, ship crews are able to quickly deploy the vehicle to survey for damage in mild to moderate currents. Requiring no certifications to operate, any qualified crew member can use the ROV to inspect for damage and evaluate the integrity of the hull. This limits dry-docking to only necessary situations, while simultaneously putting no crew members in danger for an underwater inspection.

Additionally, even when a ship is anchored, it still retains the ability to adjust positions with the current. If a diver is underneath conducting an inspection, a shift can result in a direct collision with the diver. On top of the specific dangers of navigating under ships, divers are also at risk of the regular concerns of pressurization during diving. When an ROV enters the water in lieu of a human, all of these risks are effectively eliminated.

For quick eyes underwater, the DTG3 is the most portable and cost-effective ROV from Deep Trekker. It can battle up to 2 knot currents and houses a 270 degree panning HD camera for smooth scans underneath ship hulls. Unable to effectively integrate with sonar due to its compact two-thruster design, the DTG3 is best suited for calm, clear environments.

The REVOLUTION ROV from Deep Trekker utilizes six thrusters in a larger, more robust body for optimal power through complex environments. The four vectored and two horizontal thrusters enable three different planes of movement to navigate in unorthodox patterns while maintaining a clear visual.

This larger design is best suited for hull inspections when combined with the M3000D imaging sonar. This is the best-in-class option for extremely detailed, up-close inspections through murky conditions. The enhanced 4K camera is also recommended for identifying smaller defects, and the thickness gauge or CP probe can also be integrated for hull structural evaluations.

April 4th, 2025

Join Deep Trekker and Navtech Radar at Ocean Business 2025 to...

April 3rd, 2025

Advanced ROV training at Deep Trekker Headquarters helped H2O Drones improve...

March 18th, 2025

Global Diving & Salvage levels up its underwater ROV expertise with...